Product List

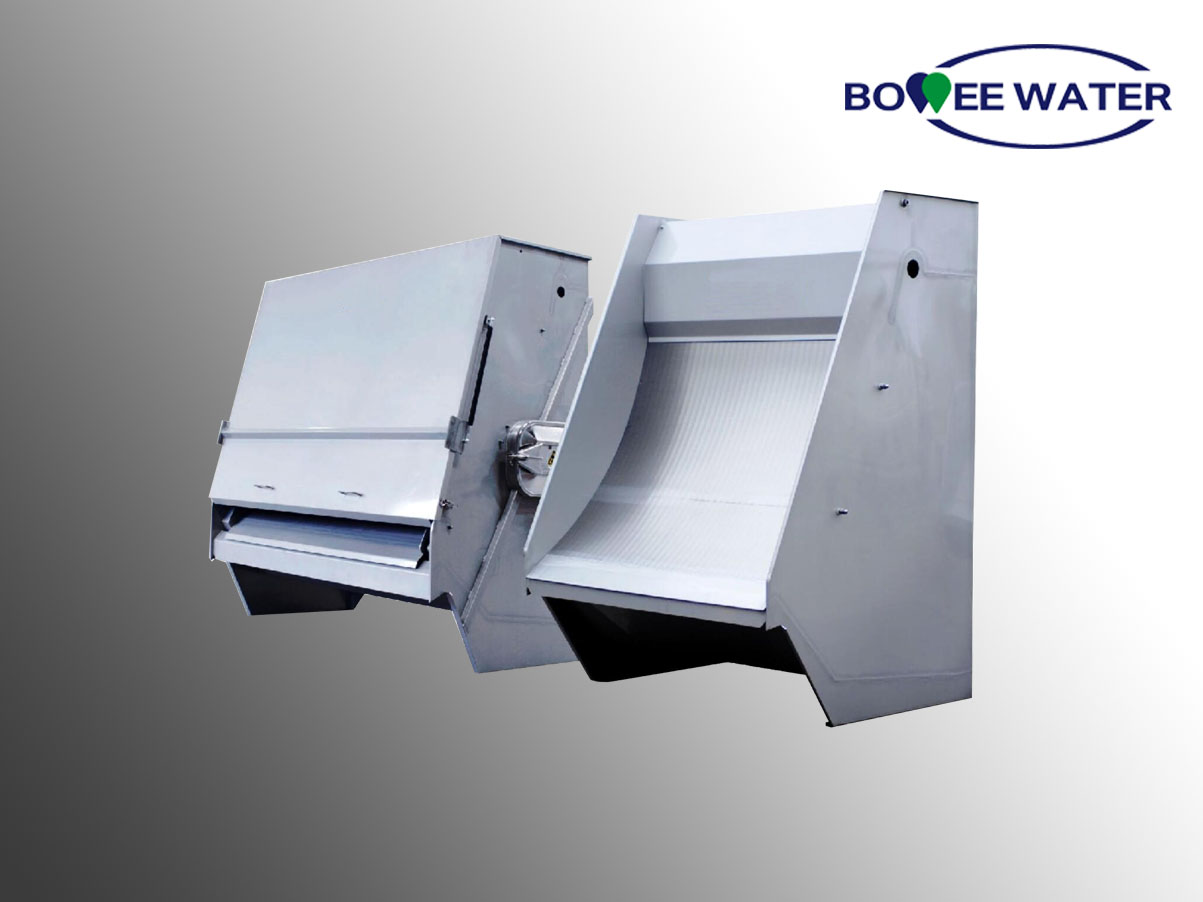

A no-moving part unit that cascades solid laden slurry down a wedge wire screen to separate solids from liquids. The slurry is pumped or gravity fed into the unit’s top chamber, flows over a full width weir and cascades down the curved screens surface.

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

Opening type: wedge wire

Opening size:0.15-5mm

-

Description

A no-moving part unit that cascades solid laden slurry down a wedge wire screen to separate solids from liquids. The slurry is pumped or gravity fed into the unit’s top chamber, flows over a full width weir and cascades down the curved screens surface. The liquid passes through the screens voids into a collection chamber below. Solid particles larger than the screens void size stay on the surface, and as this accumulating mass increases in weight/volume, gently slides down the screens surface, compacted and further dewatered as it travels down. At the bottom discharge chute, the solids simply drop off or in some applications, go for further dewatering by a drum or screw press unit.

-

Applications

Static Screen have many applications in the pretreatment of waste water for practically any kind of industry. Performance is optimum in those applications where there is no oil, a dryness greater than that obtained even by rotary screens being achieved with this system.

1. The screening of water from the plastics, paper, textile, tanning, laundry , milk industries and food industries etc…

2. Tank cleaning.

3. Screening of solids after channel bar screening in urban water cleaning.

4. Recycling of water in cleaning circuits.

-

Technical parameters

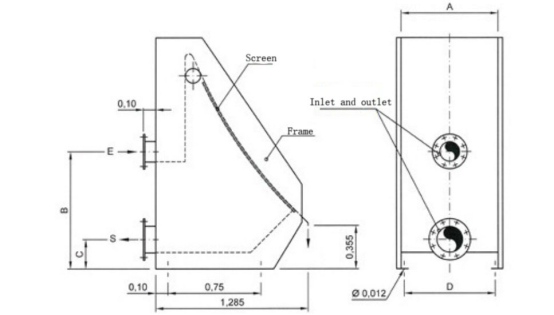

Model

Dimension(mm)

Inlet and outlet

Capacity(m3/hr) in different mesh size(mm)

A

B

C

D

Inlet

Outlet

0.5mm

0.75mm

1.0mm

1.5mm

BWSS-30

300

932

188

250

DN100

DN100

5-21

6-25

8-30

10-35

BWSS-50

500

932

215

450

DN100

DN150

6-30

8-37

10-44

13-51

BWSS-80

790

959

215

740

DN150

DN150

8-40

10-50

12-58

16-68

BWSS-120

1210

959

240

1160

DN150

DN200

13-82

18-92

25-100

30-130

-

Advantages

1. Sieve screen is offered with apertures from 0.5 mm ,1mm, 1.5mm to 3 mm;

2. Passive filtration method maximizes solids removal;

3. No moving parts, easy to set up with small installation area;

4. Self-cleaning, easy to maintain, and the running cost is zero;

5. No actuating equipment, neither vibration nor noise is produced;

6. Simple structure, operation simplicity, sturdiness;

-

Related Products